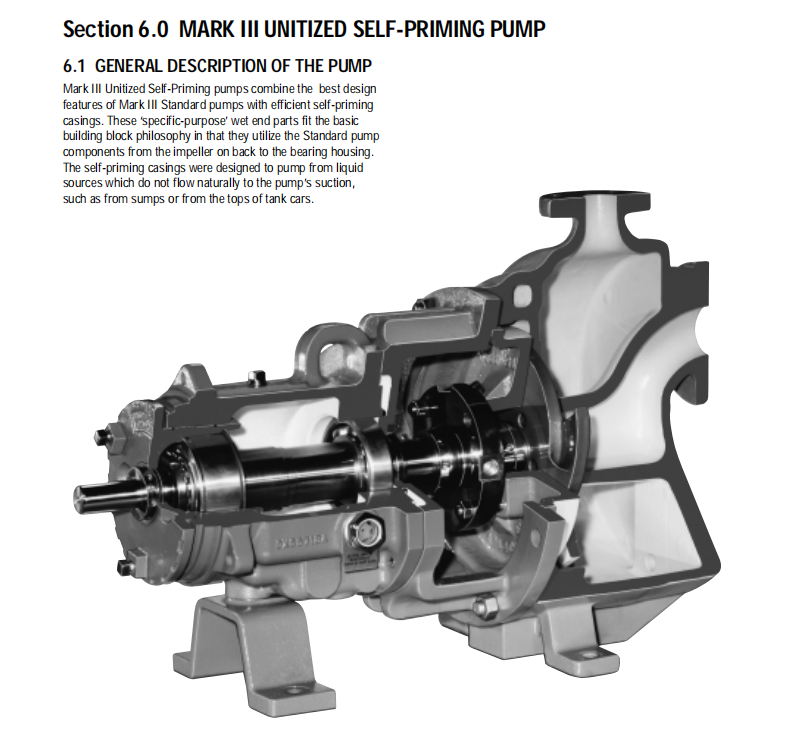

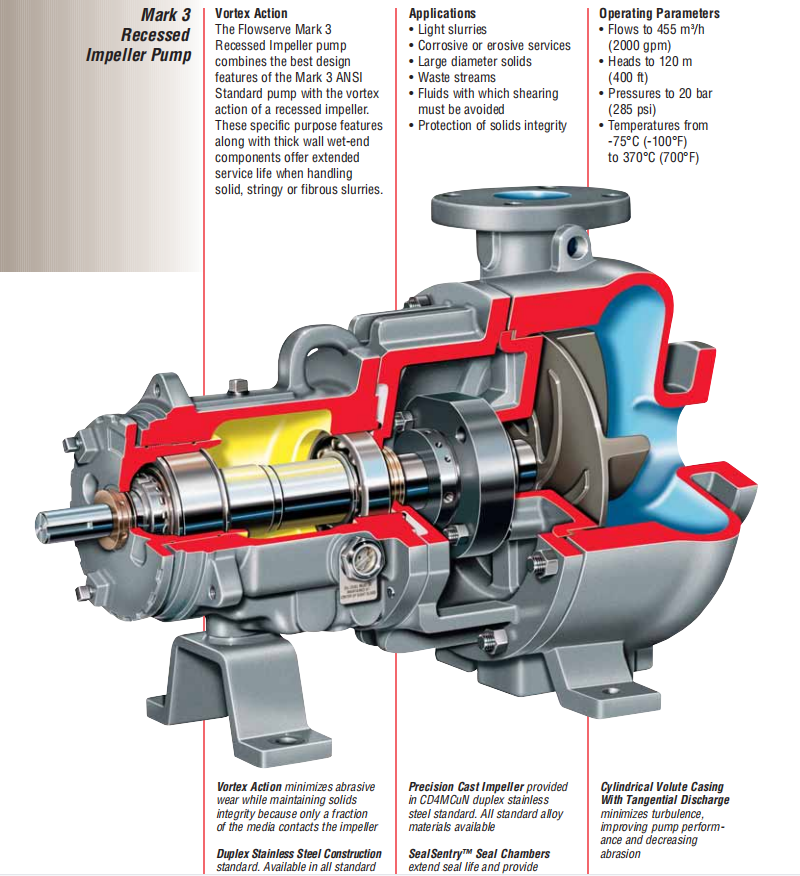

Benefits of the Mark 3 Reverse Impeller Pump

1.Our pumps could be 100% interchangeble with leading enterprise's Mark III series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

Our pump replacement parts are reliable, fee powerful alternative elements which are interchangeable with many widely known pump brands.

We manufacture a range of replacement parts which include shafts, casings, impellers, stuffing box covers, sleeves, labyrinth seals, repellers, backplates, followers and lots of greater.

MISCELLANEOUS INFORMATION

There are two basic repeller configurations, one to accommodate only positive suction heads of fairly large magnitude and another dual head repeller that will accommodate suction heads that may be negative as well as positive; while the pump is in operation, however, the magnitude of its positive head capability is reduced. It should be understood that under no circumstances can the pump be started and primed unless the suction piping is flooded with liquid. This requirement would preclude the use of a SEALMATIC pump as a normally employed self-priming pump.

REPELLER SELECTION INSTRUCTIONS

To select a repeller, compare the range of suction pressures expected in each application to the repeller characteristic curves. The curves show the range of static suction heads for which the repeller has been tested and found to prevent leakage. These curves are published in the “Repeller Selection Curves” brochure.

Some liquids have physical properties which tend to reduce the stability of the air-liquid interface created by the repeller in the repeller chamber. This instability may lead to a misting of liquid which can result in a small stream of leakage or a constant dripping from the shaft area. Generally, selecting a repeller which will operate toward the high end of its suction head capability will assure a more stable air-liquid interface and thus avoid this problem.

Caution must be exercised in applying Sealmatic pumps for liquids having surface tensions below 50 dynes per cm at 3600 rpm and below 30 dynes per cm at 1800 rpm. Such liquids have a greater tendency to be atomized by the repeller vanes moving through the air-liquid interface. The resultant vapor may then condense on the non-wetted internal surfaces and drip from the shaft area.

In certain applications of Sealmatic pumps, air may be entrained in the liquid being pumped. Figure 63 shows the typical rate of air ingress for the 71/2 in (191 mm) diameter dual head repeller in a 10 in (254 mm) pump at 1800 rpm. Approximately the same rate of ingress should be expected with other repellers. Note that air ingress can be kept to an extremely low level by selecting a repeller to operate near its maximum suction head capability.

Horsepower consumed by the repeller is shown on the repeller performance characteristic curves. This horsepower is added to the horsepower taken from the standard pump performance curve to determine the total water horsepower requirement for the Sealmatic pump.

Related News

Submitted successfully

We will contact you as soon as possible