Mark III Pump Manual

1.Our pumps could be 100% interchangeble with leading enterprise's Mark III series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

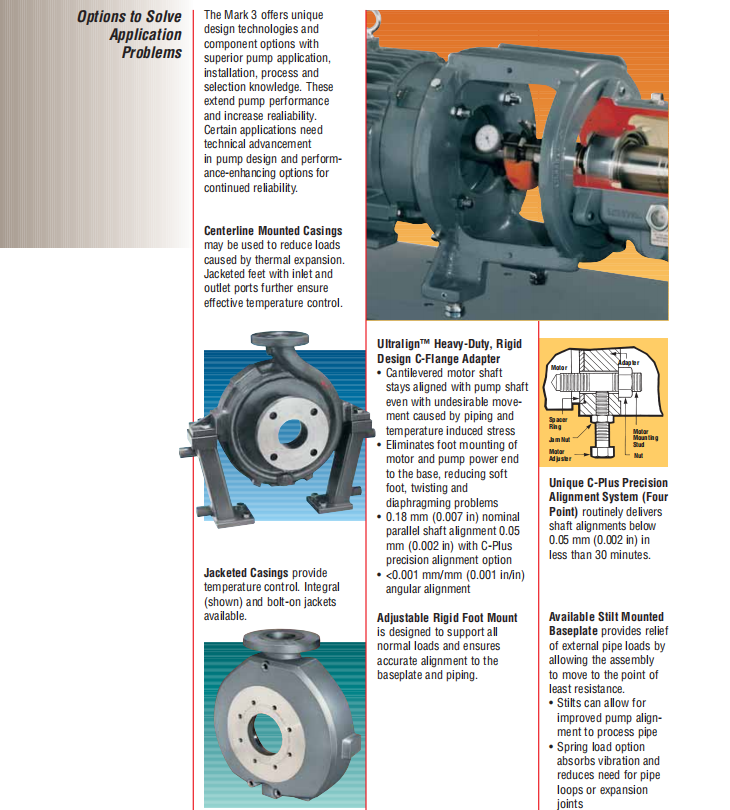

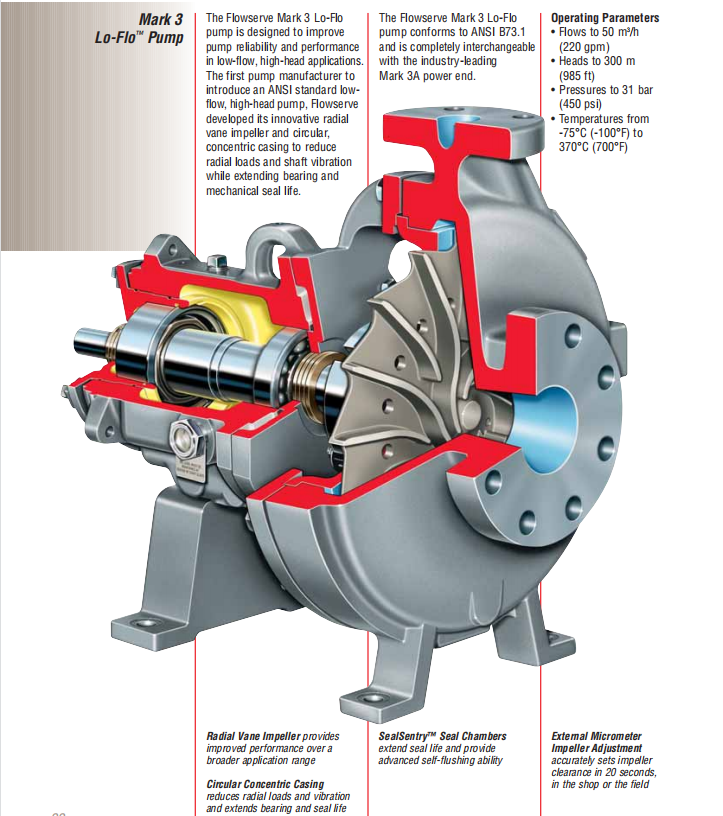

Prolonged mechanical seal and bearing lifestyles through strong shaft and bearing designs that still limit shaft deflection.

Rapid and accurate impeller placing with the industry's maximum revolutionary external impeller adjustment mechanism.

In-keep reverse vane impeller adjustment with the most effective pump that takes full gain of the again pull-out design.

STARTING THE PUMP AND ADJUSTING FLOW

1. Open the suction valve to full open position. It is very important to leave the suction valve open while the pump is operating. Any throttling or adjusting of flow must be done through the discharge valve. Partially closing the suction valve can create serious NPSH and pump performance problems.

Never operate pump with both the suction and discharge valves closed. This could cause an explosion.

2. A standard centrifugal pump will not move liquid unless the pump is primed. A pump is said to be “primed” when the casing and the suction piping are completely filled with liquid. Open discharge valve a slight amount. This will allow any entrapped air to escape and will normally allow the pump to prime, if the suction source is above the pump. When a condition exists where the suction pressure may drop below the pump’s capability, it is advisable to add a low pressure control device to shut the pump down when the pressure drops below a predetermined minimum.

3. All cooling, heating, and flush lines must be started and regulated.

4. Start the driver (typically, the electric motor).

5. Slowly open the discharge valve until the desired flow is reached, keeping in mind the minimum flow restrictions listed above.

It is important that the discharge valve be opened within a short interval after starting the driver. Failure to do this could cause a dangerous build up of heat, and possibly an explosion.

6. Reduced capacity

Avoid running a centrifugal pump at drastically reduced capacities or with discharge valve closed for extended periods of time. This can cause severe temperature rise and the liquid in the pump may reach its boiling point. If this occurs, the mechanical seal will be exposed to vapor, with no lubrication, and may score or seize to the stationary parts. Continued running under these conditions when the suction valve is also closed, can create an explosive condition due to the confined vapor at high pressure and temperature.

Thermostats may be used to safeguard against over heating by shutting down the pump at a predetermined temperature.

Safeguards should also be taken against possible operation with a closed discharge valve, such as installing a bypass back to the suction source. The size of the bypass line and the required bypass flow rate is a function of the input horsepower and the allowable temperature rise.

7. Reduced Head

Note that when discharge head drops, the pump’s flow rate usually increases rapidly. Check motor for temperature rise as this may cause overload. If overloading occurs, throttle the discharge.

8. Surging Condition

A rapidly closing discharge valve can cause a damaging pressure surge. A dampening arrangement should be provided in the piping.

Related News

Submitted successfully

We will contact you as soon as possible