Model 3196 Chemical Process Pumps

1.Our pumps could be 100% interchangeble with leading enterprise's 3196 series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

When the 3196 ANSI Pump was first introduced in 1961, it immediately became the standard in the industry. Today, the number of installations attest to its remarkable performance. Users in chemical, petrochemical, pulp & paper, primary metals, food & beverage and general industries know they can make no better choice than the best.

1. Application:

Chemical Processing

General Industries

Mining

Water Resources

Power Generation

Primary Metals

Pulp and Paper

Oil and Gas

2.Capacities to 7000 GPM (1590 m³ /h)

Heads to 730 feet (223 m)

Temperatures to 700° F (371° C)

Pressures to 375 PSIG (26 bar)

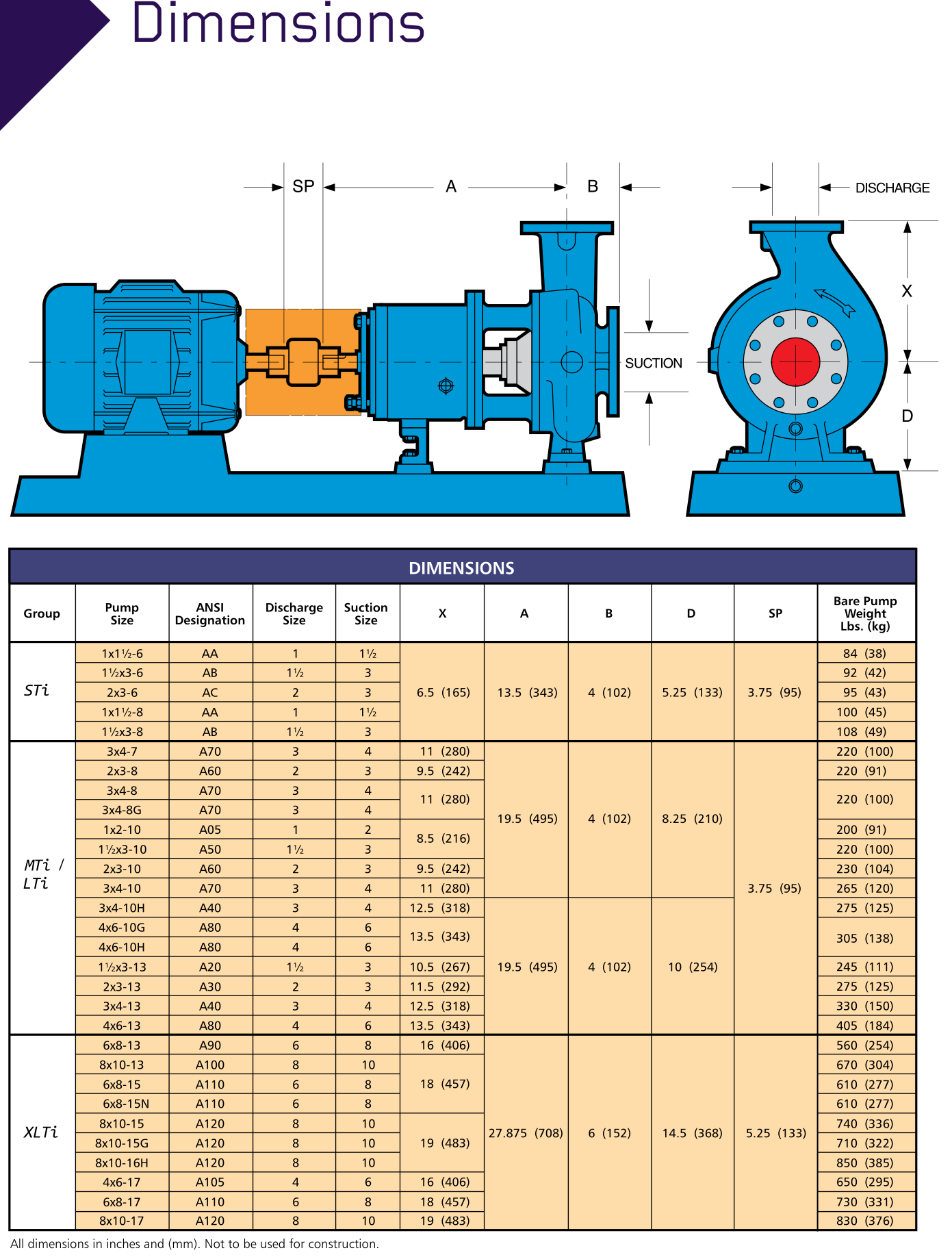

3. Available Size:6’’-15’’

4.Open impeller

Designed for long-term, maintainable performance and minimum hydraulic loads for maximum reliability.

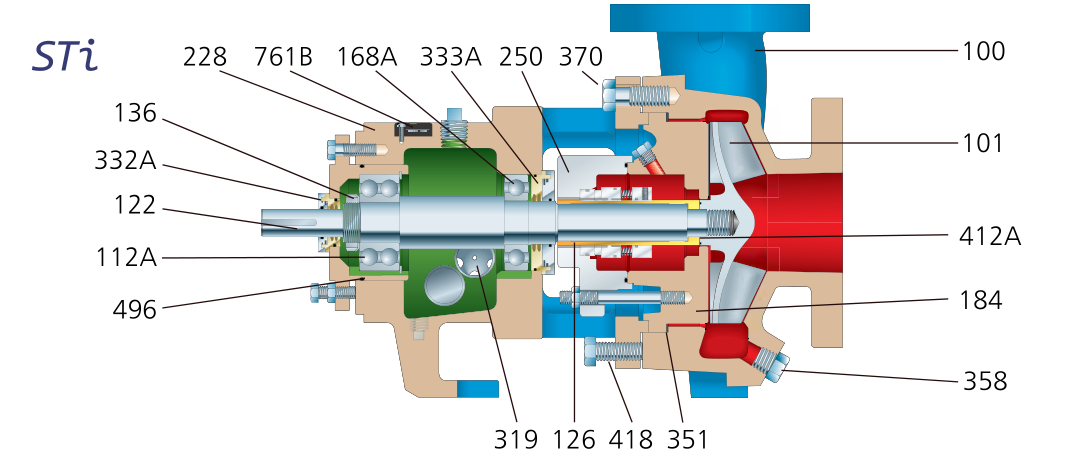

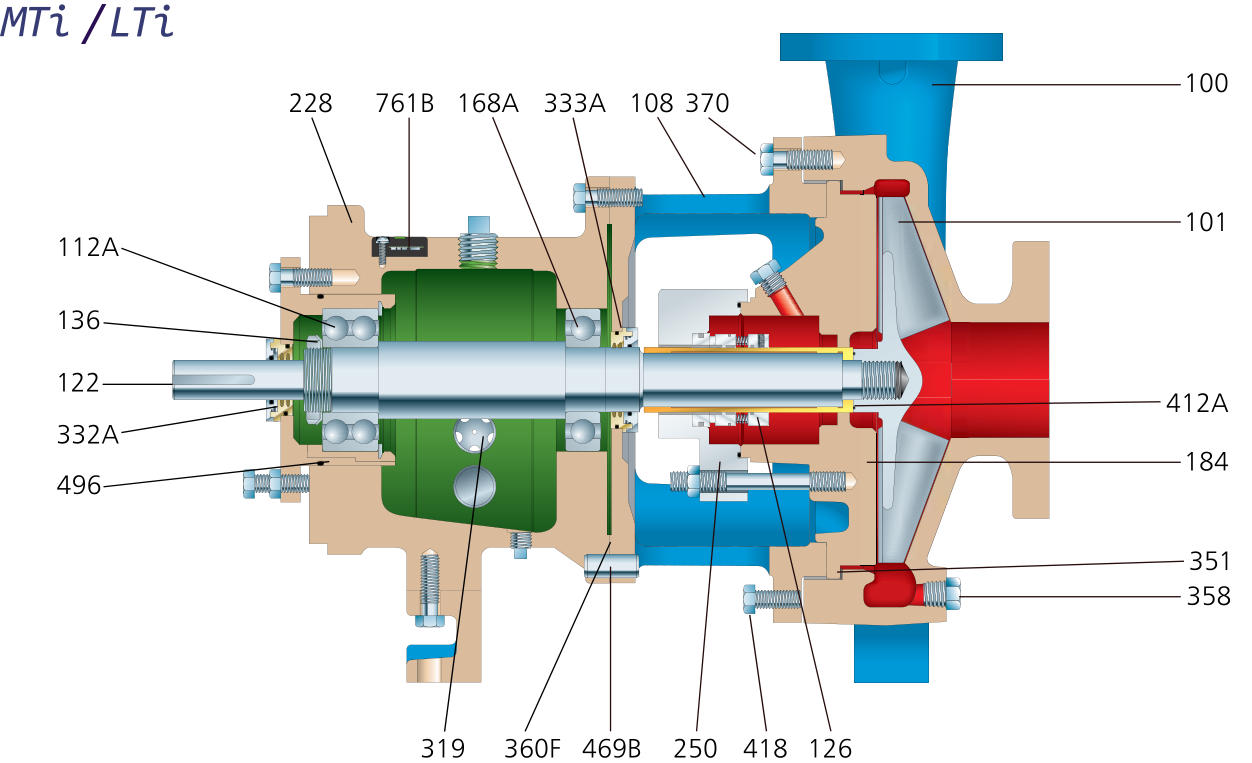

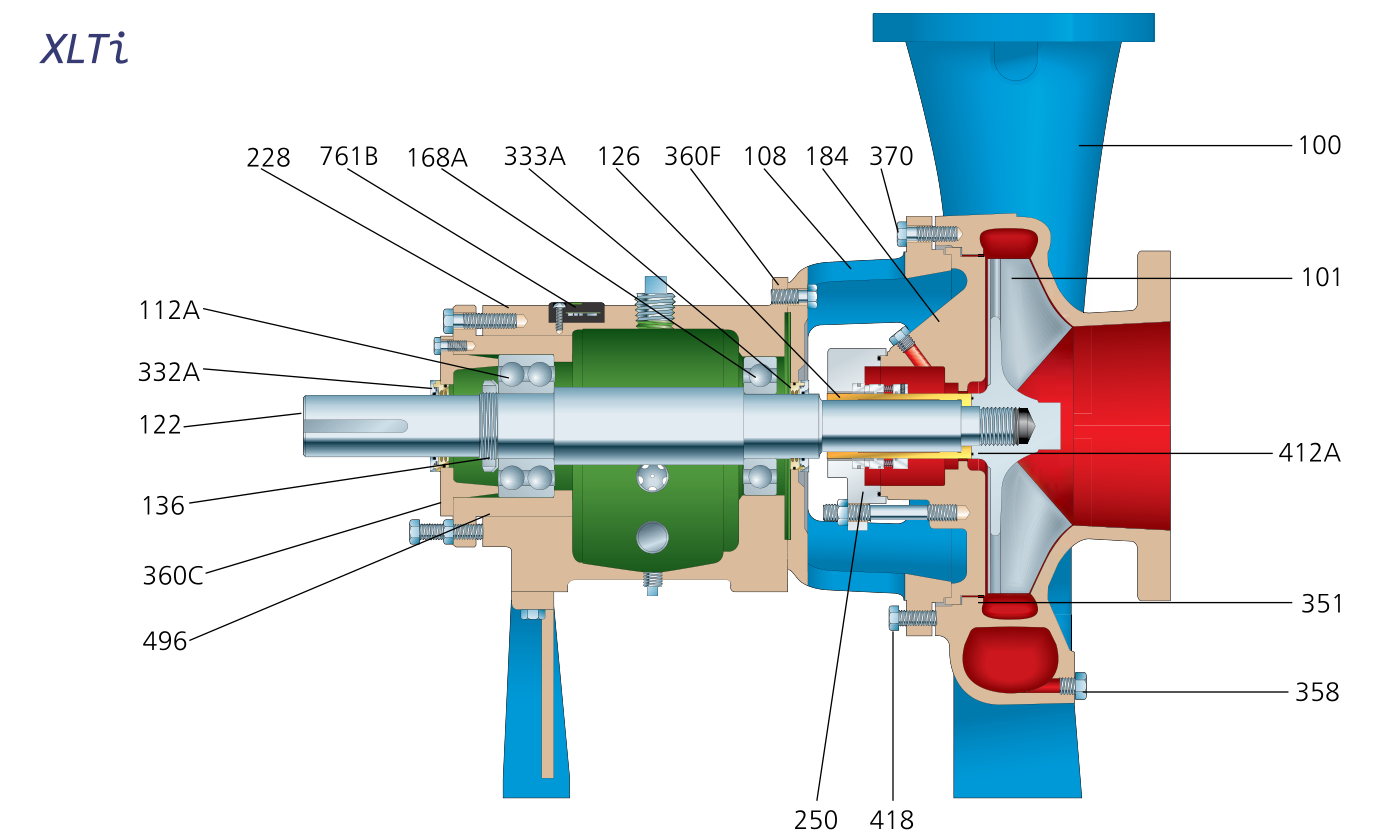

5.CASING

#150RF flange

6.Seal Chamber

Standard bore, big bore and taper bore

7.Power End

Designed for optimum bearing life, effective oil cooling, and minimum shaft deflection. Onboard

condition monitoring provides early warning of potential failures, before they occur.

8.Material available

Part Name | Material | ||||||

Ductile Iron | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Casing | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Impeller | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Cover | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Frame | Ductile Iron | ||||||

Bearing Housing | Ductile Iron | ||||||

Adaptor | Ductile Iron | ||||||

Shaft | 316SS/4140 | ||||||

Sleeve | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Related News

Submitted successfully

We will contact you as soon as possible