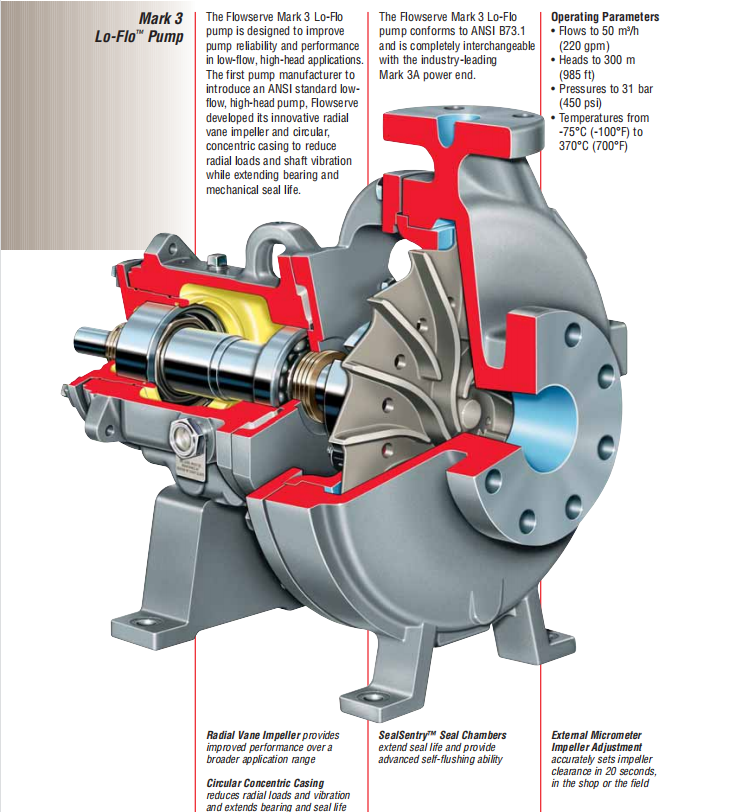

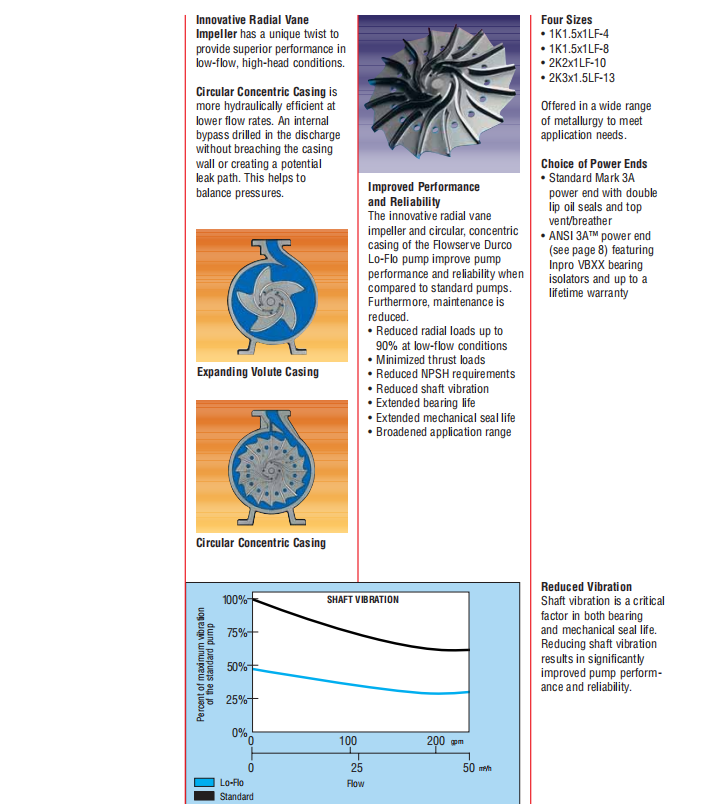

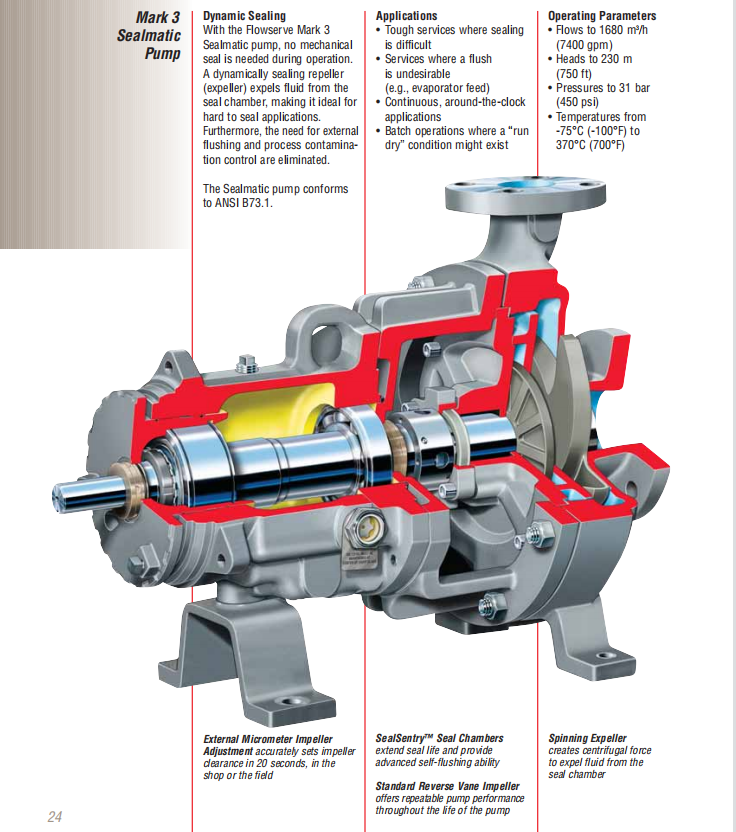

Mark 3 Pump Operation

1.Our pumps could be 100% interchangeble with leading enterprise's Mark III series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

Our Pump substitute components are reliable, cost effective replacement elements which might be interchangeable with durco etc widely known pump manufacturers.

We manufacture more than a few substitute parts including shafts, casings, impellers, stuffing container covers, sleeves, labyrinth seals, repellers, backplates, fans and plenty of more.

MAINTENANCE

PREVENTIVE MAINTENANCE

A procedure for keeping accurate maintenance records is a critical part of any program to improve pump reliability. There are many variables that can contribute to pump failures. Often long term and repetitive problems can only be solved by analyzing these variables through pump maintenance records.

NEED FOR CLEANLINESS

One of the major causes of pump failure is the presence of contaminants in the bearing housing. This contamination can be in the form of moisture, dust, dirt and other solid particles such as metal chips. Contamination can also be harmful to the mechanical seal (especially the seal faces) as well as other parts of the pumps. For example, dirt in the impeller threads could cause the impeller to not be seated properly against the shaft.This, in turn, could cause a series of other problems. For these reasons, it is very important that proper cleanliness be maintained. Some guidelines are listed below.

After draining the oil from the bearing housing, periodically send it out for analysis. If it is contaminated, determine the cause and correct. The work area should be clean and free from dust, dirt, oil, grease, etc. Hands and gloves should be clean.Only clean towels, rags, and tools should be used. To simplify maintenance, it is recommended that the “Durco Tool Kit”,shown in Figure 21, to used. This tool kit includes a handy impeller wrench, which simplifies installation and removal of the impeller. It also contains “nose cones” which protect shaft threads and O-rings during maintenance.

Related News

Submitted successfully

We will contact you as soon as possible