ANSI B73.1 Chemical Process Pump

1. Our pumps could be 100% interchangeble with leading enterprise’s 3196 series.

2. The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

The 3196 ANSI Series is available in a extensive variety of sizes, capacities and materials to match sincerely any manner-fluid software.

1.Application:

Chemical Processing

General Industries

Mining

Water Resources

Power Generation

Primary Metals

Pulp and Paper

Oil and Gas

2.Capacities to 7000 GPM (1590 m³ /h)

Heads to 730 feet (223 m)

Temperatures to 700° F (371° C)

Pressures to 375 PSIG (26 bar)

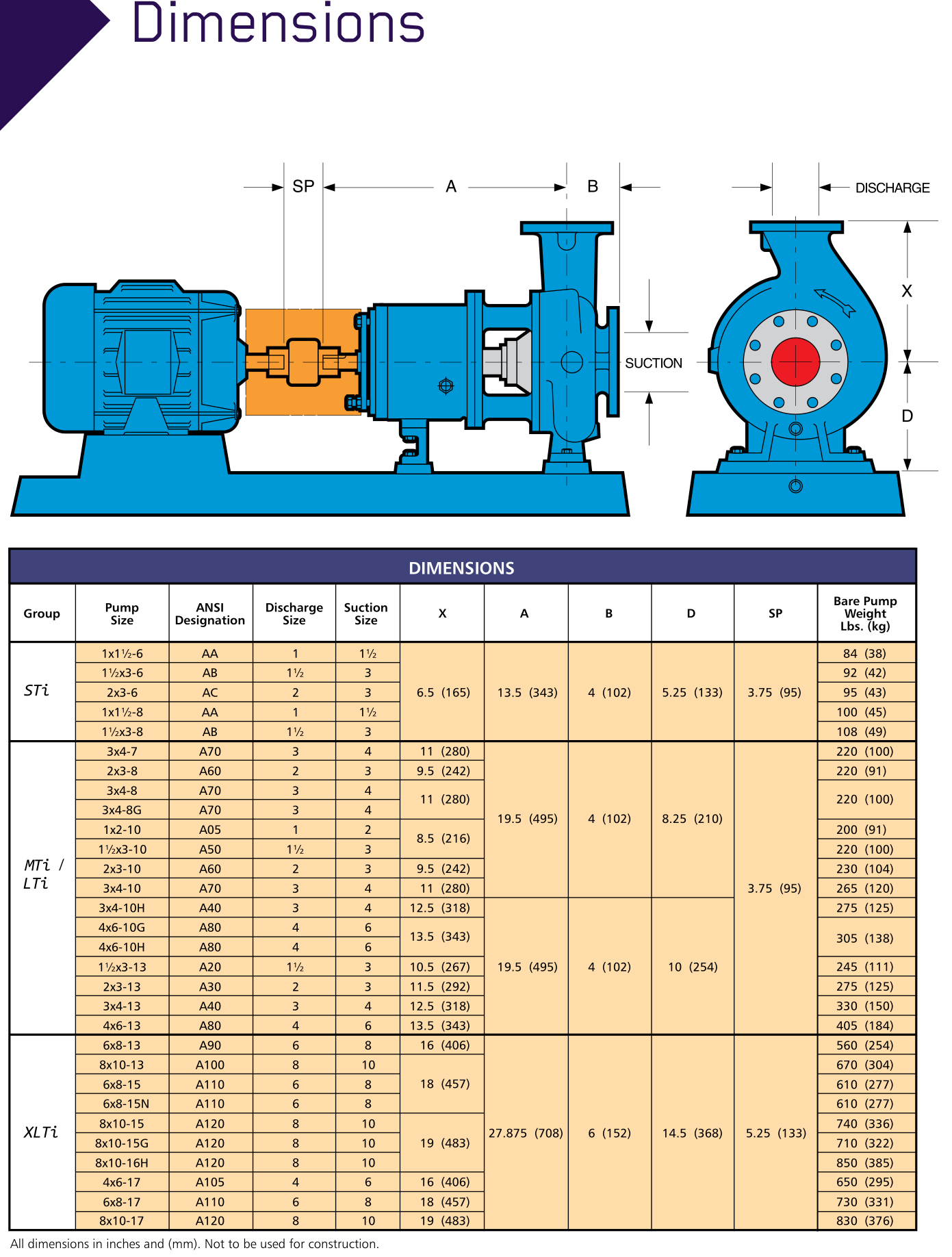

3.Available Size:6’’-15’’

4.Impeller

Designed for long-term, maintainable performance and minimum hydraulic loads for

maximum reliability.

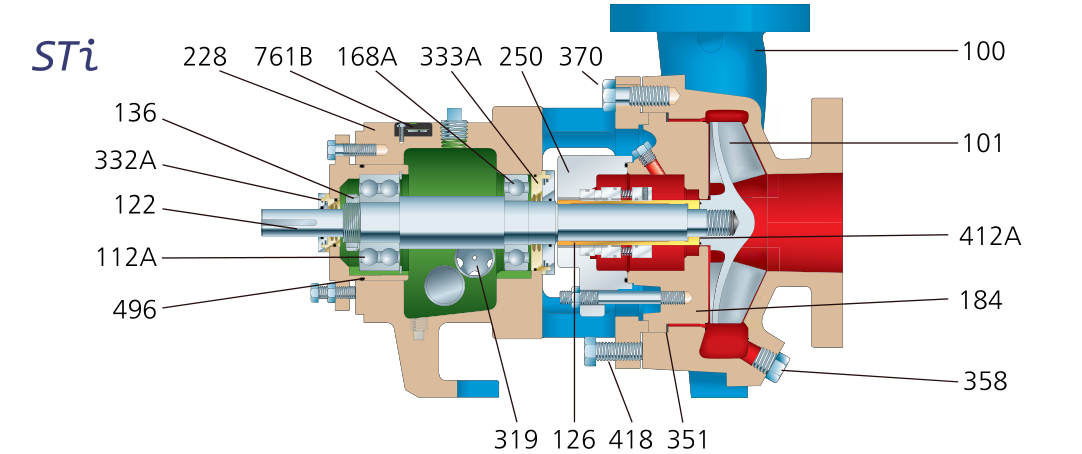

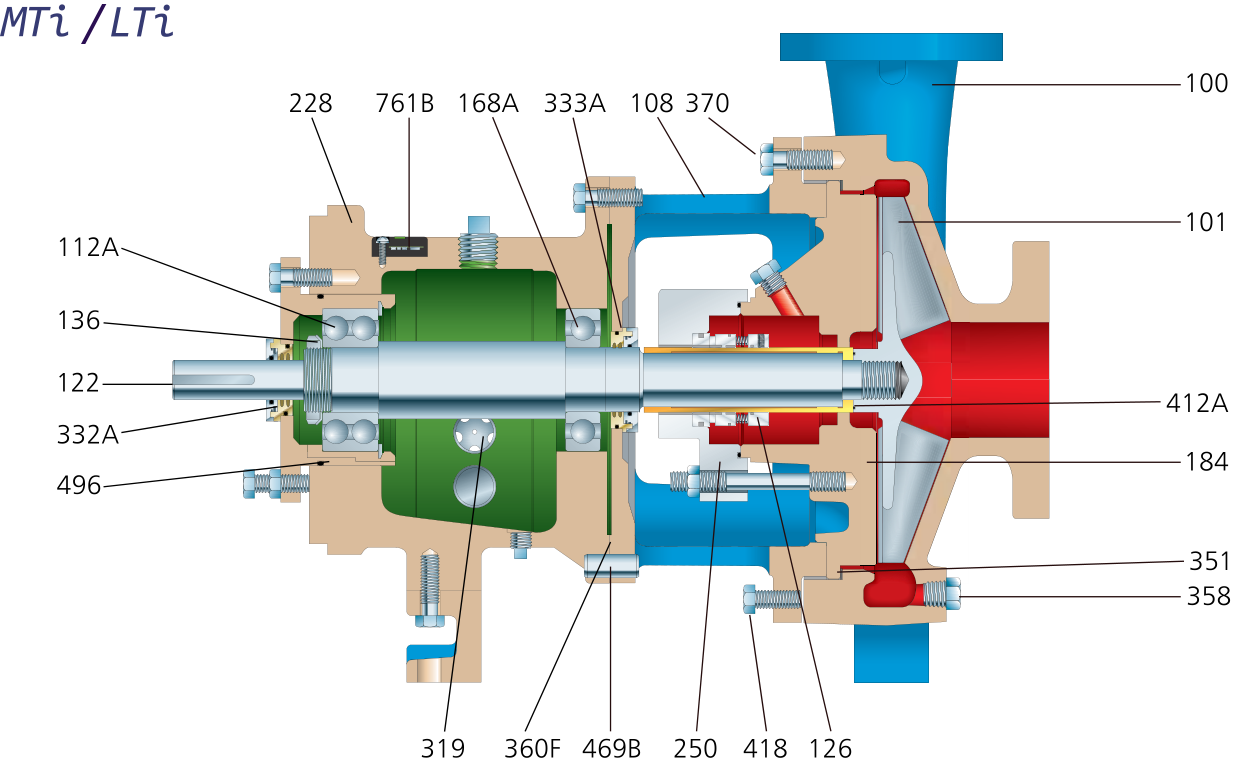

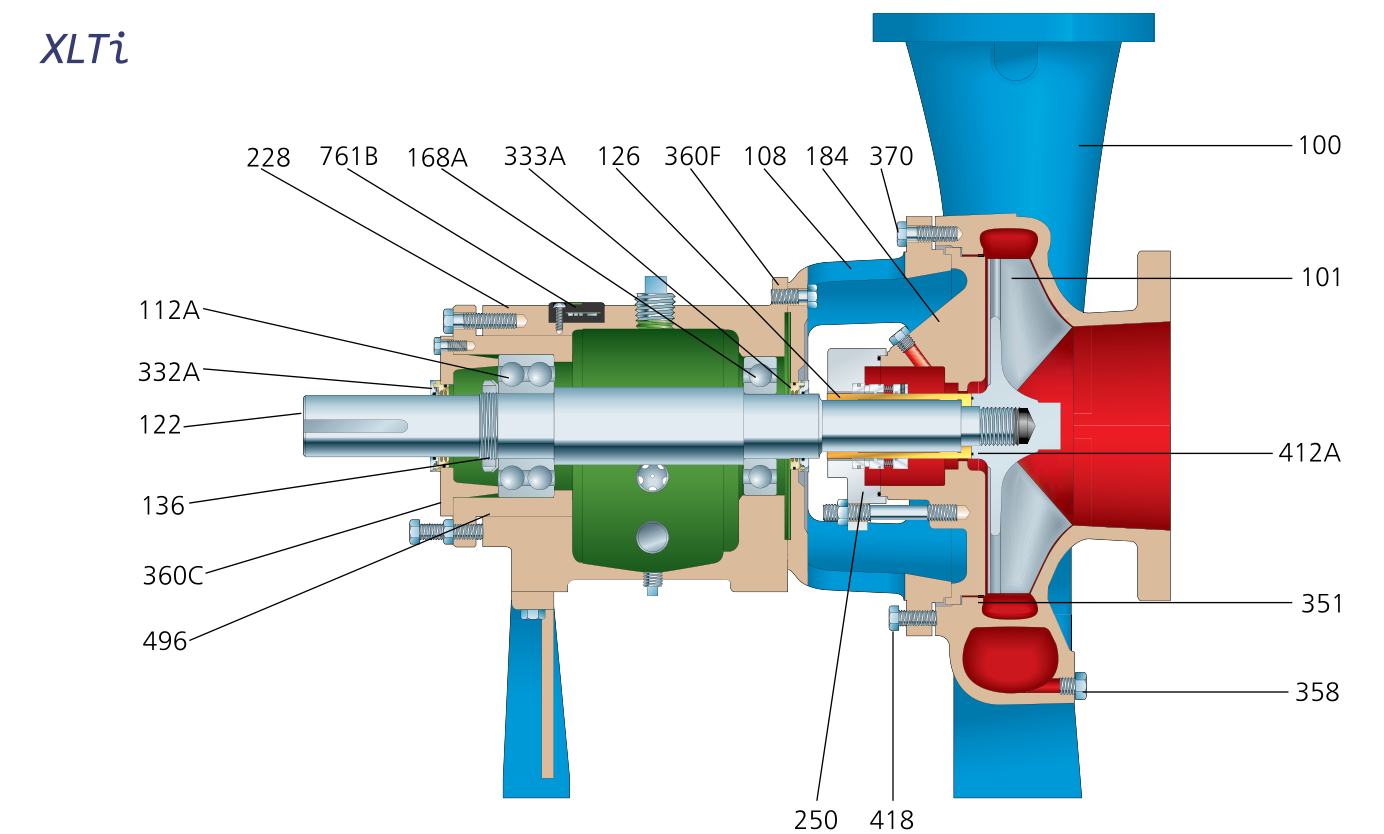

CASING

• Top centerline discharge for air handling, self-venting.

• Class 150 pumps have Class 300 wall thickness as standard.

• Back pull-out design.

• Integral feet.

Seal Chamber

Designed for favorable seal environment —proper heat dissipation and lubrication of seal faces.

The design must also be able to handle tough services: liquids containing solids, air or vapors.

Power End

Designed for optimum bearing life, effective oil cooling, and minimum shaft deflection. Onboard

condition monitoring provides early warning of potential failures, before they occur.

5.Fully open impeller is the best design for the chemical process industries services. Ideally suited for corrosives and abrasives, handles solids and stringy fibers with ease. Allows for simple restoration of clearances when wear takes place. Back pump-out vanes reduce pressure on the shaft seal, reduce axial thrust on the bearings.

Our seal chambers allow seals to run cooler with better face lubrication. Keep solids, air and vapors away from the seal faces for extended seal life.

Our power ends design maximizes reliability and Mean Time Between Failure (MTBF). Severe-duty bearings increase bearing life 2-5 times, while onboard condition monitor gives visible indication of general pump health

6. Impeller Advantage: 1.Two Times More Wear Area 2.Maintained High-Performance 3.Minimum Hydraulic Loads

7.

Part Name | Material | ||||||

Ductile Iron | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Casing | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Impeller | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Cover | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Frame | Ductile Iron | ||||||

Bearing Housing | Ductile Iron | ||||||

Adaptor | Ductile Iron | ||||||

Shaft | 316SS/4140 | ||||||

Sleeve | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

8.Outstanding Features for Outstanding Performance

Extended Pump Life

Ease of Maintenance

• Back Pull-out Design

• External Impeller Adjustment

• Maximum Interchangeability

Optimum Hydraulic Performance

• Fully Open Impeller

• Full 50/60 Hz Coverage

• 29 Sizes

• Computerized Pump Selection

Safety

• ANSI B15.1 Coupling Guard

• Ductile Iron Frame Adapter

Related News

Submitted successfully

We will contact you as soon as possible