Mark III Pump

1.Our pumps could be 100% interchangeble with leading enterprise's Mark III series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

1.Application:

Chemical Processing

General Industries

Mining

Water Resources

Power Generation

Primary Metals

Pulp and Paper

Oil and Gas

2.Capacities to 7000 GPM (1590 m³ /h)

Heads to 730 feet (223 m)

Temperatures to 700° F (371° C)

Pressures to 375 PSIG (26 bar)

3.Available Size:6’’-16’’

4.

Part Name | Material | ||||||

Ductile Iron | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Casing | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Impeller | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Cover | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

Frame | Ductile Iron | ||||||

Bearing Housing | Ductile Iron | ||||||

Adaptor | Ductile Iron | ||||||

Shaft | 316SS/4140 | ||||||

Sleeve | 316SS | CD4MCu | Alloy 20 | Nickel | Hastelloy C | Titanium | |

5.Functions and benefits

A.Specific opposite vane impeller is the handiest impeller layout that gives repeatable pump performance at some point of the existence of the pump.

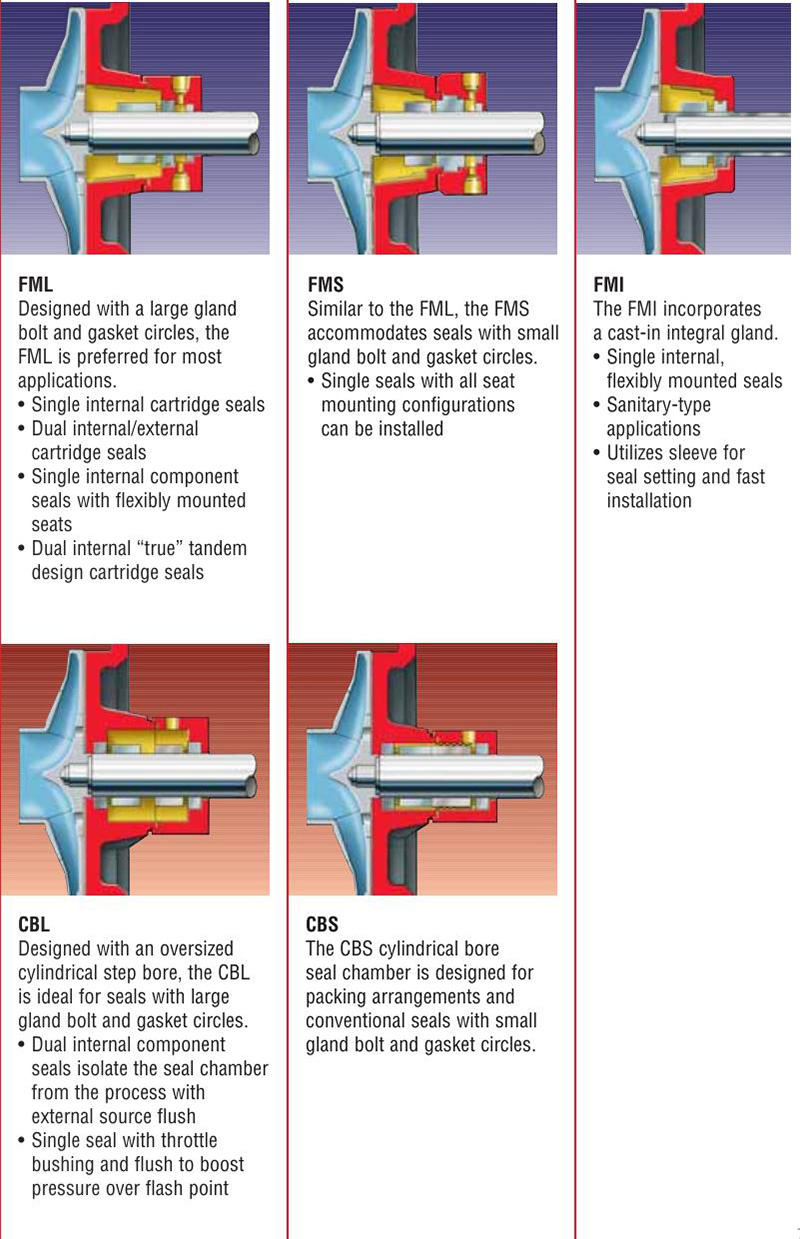

B.Seal chambers characteristic progressive float modifiers to increase seal life and offer advanced

Self-flushing functionality.

C.Outside micrometer impeller adjustment correctly units impeller clearance in 20 seconds, in the shop or in the subject.

D.Biggest shaft and bearing additives in trendy asme pumps expand bearing life and reduce shaft deflection and vibration.

E.Lower back pull-out design allows elimination of rotating detail without putting off casing, piping or motor.

F.Heavy-obligation pump cease and force end bearings are decided on for lengthy existence and reliability.

Related News

Submitted successfully

We will contact you as soon as possible