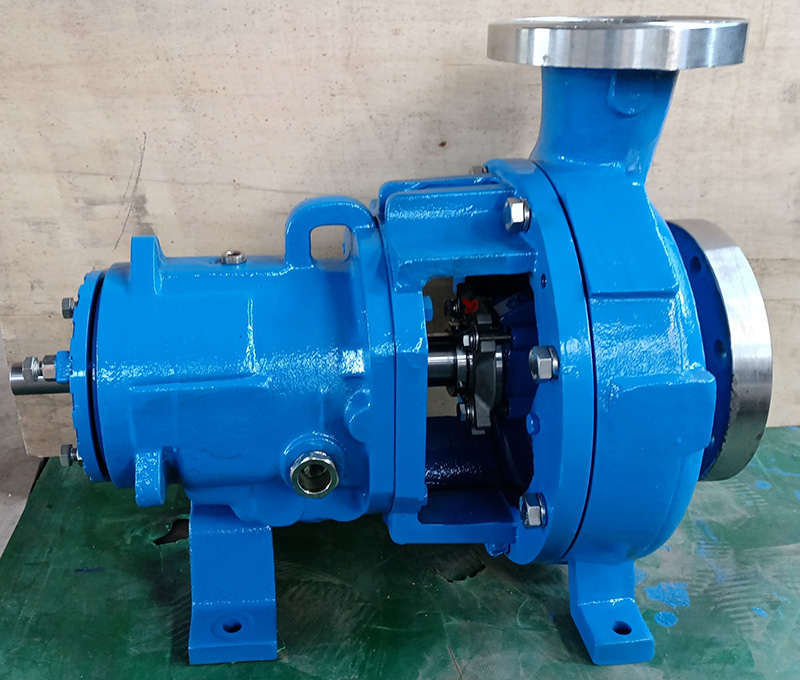

Mark 3 Pump

1.Our pumps could be 100% interchangeble with leading enterprise's Mark III series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

SUMMARY AND DESCRIPTION

Product Summary

Type: Single stage, horizontal, overhung, end suction, centerline discharge, back pull-out, fully compliant with ASME B73.1-2001

Lead design center: Dayton GTC

Lead manufacturing center: Chesapeake

Secondary manufacturing center: Newark

General Description

The Mark 3 is recognized worldwide as the premier name in ANSI chemical process pumps. The advanced design and precision manufacture results in a rugged, heavy-duty pump that will provide reliable, dependable performance in the most demanding services. Below are some of the highlights of the Mark 3 pumps. The Mark 3 bulletin, contained in Section 2,should be carefully studied for details.

Available Sizes and Range of Service

The Mark 3 line covers a broad hydraulic range:

• Sizes – 30

– Group 1 – 7

– Group 2 – 16

– Group 3 – 7

• Capacities

– 60 Hz to 1680 m3/h (7400 gpm)

– 50 Hz to 1390 m3/h (6120 gpm)

• Heads

– 60 Hz to 300 m (985 ft)

– 50 Hz to 200 m (655 ft)

Applications

Mark 3 pumps find use in applications ranging from water to the most corrosive chemicals.

Construction Features

There is a very high degree of interchangeability in the Mark 3 family. The 30 sizes that comprise the family are built with only three different power frames. The charts at right summarize the interchangeability.

Features and Benefits

The Mark 3 possesses many unique features and benefits; however,there are three distinct features that differentiate it from other ANSI pumps. These features are the power end designs, the Mark 3 reverse vane impeller, and the SealSentry seal chambers. Below is a brief summary of these features with their corresponding benefits.

Related News

Submitted successfully

We will contact you as soon as possible