We has developed an extrusion process which enables industrial molders to launch their own epp production by developing their proprietary formulations and Borealis PP resin as raw material.

Main benefits

Adjustable bulk density from 25 g/l to 150 g/l and bead sizes in the range of 3-5 mm

High toughness

Good thermal insulation properties

High temperature resistance

High moisture- and chemical resistance

High color fastness

High sound absorption

Easy cleaning

Easily recyclable (nontoxic, free of heavy metal)

Main applications

Multiple use as transport and storage boxes

Various thermal isolation applications

Automotive industry

Furniture and toys industry

Exercise balls and rollers

Load carriers

White goods protective packaging

Thermo boxes

Our unique foam extrusion team presents its newest development: Extrusion based expanded polypropylene. The extrusion process enables industrial molders to launch their own ePP production by developing their proprietary formulations with Borealis PP resin as raw material.

Borealis has developed a particular high melt strength PP grade particularly for the foam extrusion process, ePP beads produced with this resin can be molded using low steam pressure and standard molding Equipment.

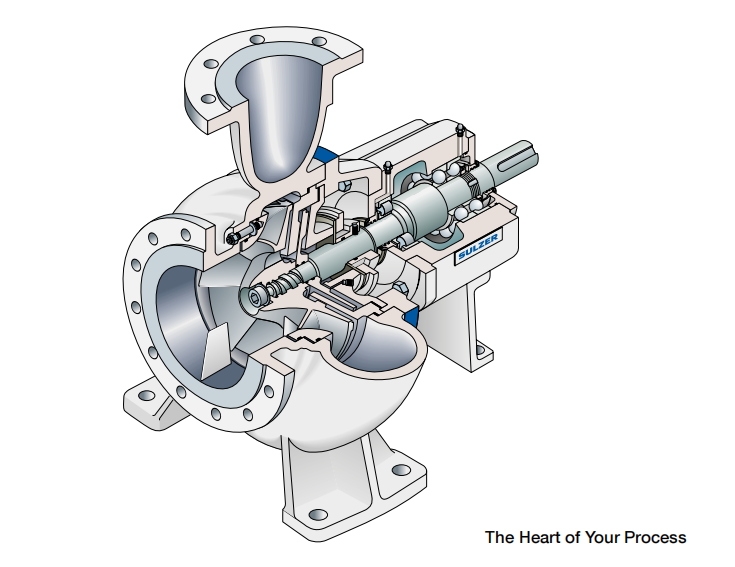

New reliable foam extrusion process for production of ePP beads

The combination of a high-resolution loss in weight feeding system, a tailor-made twin screw extruder and an accurate direct injection of blowing agents such as carbon dioxide or isobutane into the PP melt ensures product specific characteristics and flexibility for a huge field of applications for the ePP industry.

Our unique melt cooling technology and an individual designed underwater pelletizing system completes the extrusion foam process for customized beads production.

Related News

Submitted successfully

We will contact you as soon as possible