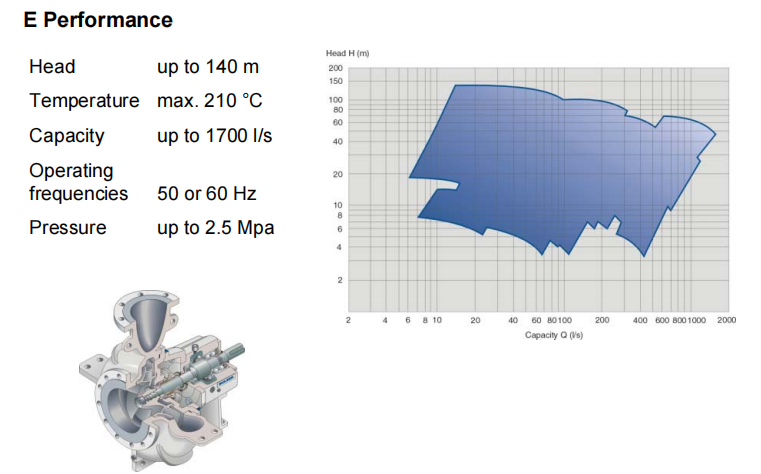

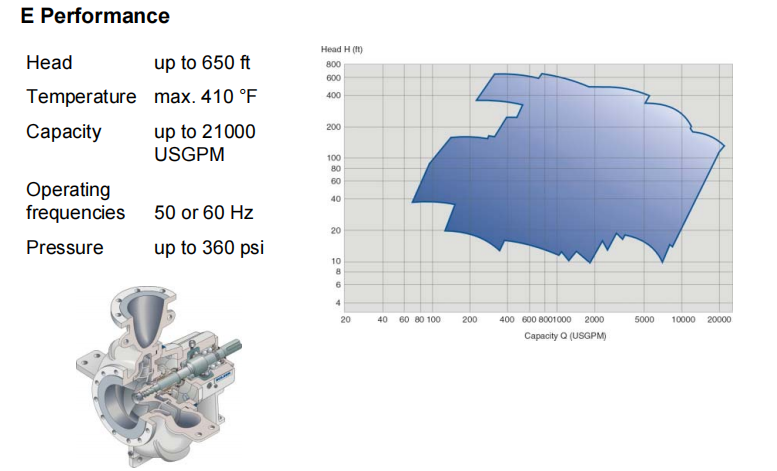

EPP Pump Hydraulic Design

Our pumps could be 100% interchangeble with leading enterprise’s EPP series.

Our unique foam extrusion team presents its newest development: Extrusion based expanded polypropylene. The extrusion process enables industrial molders to launch their own ePP production by developing their proprietary formulations with Borealis PP resin as raw material.

Borealis has developed a particular high melt strength PP grade particularly for the Sulzer foam extrusion process, ePP beads produced with this resin can be molded using low steam pressure and standard molding Equipment.

Standardization

APP, ARP, ASP, EPP, NPP, NRP, NSP, WPP, WRP and WSP pumps are designed in a similar way using the same components.

•246 pumps

•80 casing covers

•6 common bearing units

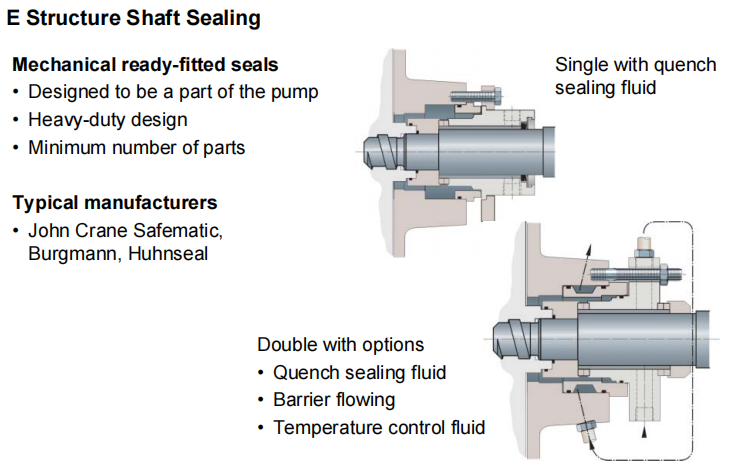

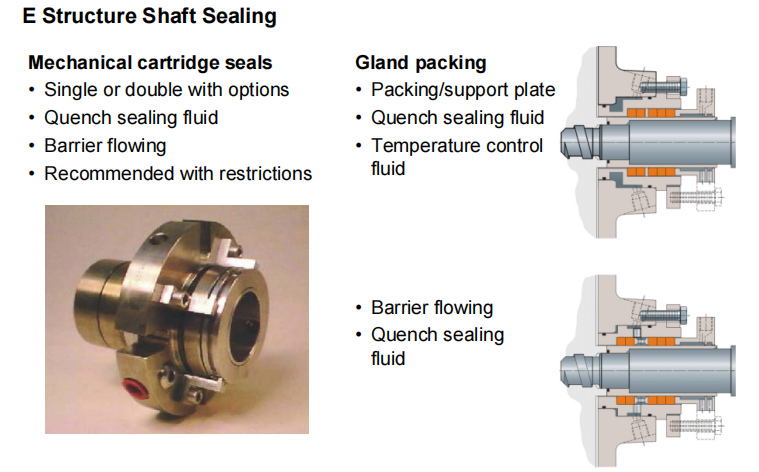

•6 common shaft seal sizes

•common sealing water equipment

•common couplings and coupling guards

•common baseplates

Related News

Submitted successfully

We will contact you as soon as possible