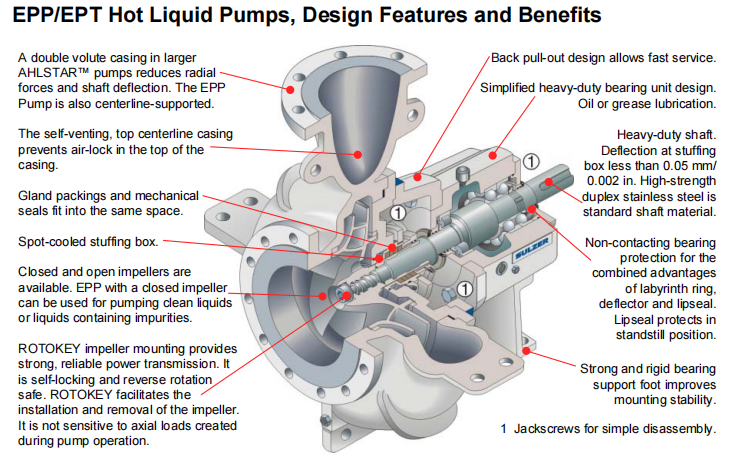

EPP Hot Liquid Pumps

Our pumps could be 100% interchangeble with leading enterprise’s EPP series.

New reliable foam extrusion process for production of ePP beads

The combination of a high-resolution loss in weight feeding system, a tailor-made twin screw extruder and an accurate direct injection of blowing agents such as carbon dioxide or isobutane into the PP melt ensures product specific characteristics and flexibility for a huge field of applications for the ePP industry.

Unique melt cooling technology and an individual designed underwater pelletizing system completes the extrusion foam process for customized beads production.

Fundamental blessings

Adjustable bulk density from 25 g/l to one hundred fifty g/l and bead sizes within the range of three-5 mm

High sturdiness

Suitable thermal insulation residences

High temperature resistance

High moisture- and chemical resistance

Excessive color fastness

Excessive sound absorption

Easy cleaning

Without problems recyclable (dependable, free of heavy metal)

Principal packages

More than one use as transport and storage containers

Various thermal isolation programs

Automotive enterprise

Furnishings and toys enterprise

Exercising balls and rollers

Load providers

White items protecting packaging

Thermo packing containers

Related News

Submitted successfully

We will contact you as soon as possible