3196 Series ANSI B73.1 Chemical Pump

1.Our pumps could be 100% interchangeble with leading enterprise' s 3196 series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

Chemical Process Pumps

Designed for Total Range of

Industry Services

I Capacities to 7000 GPM (1364 m 3 /h)

I Heads to 730 feet (223 m)

I Temperatures to 700°F (371° C)

I Pressures to 375 PSIG (2586 kPa)

Product Description:

The 3196 ANSI series is to be had in a huge variety of sizes, capacities and materials to match virtually any system-fluid utility.

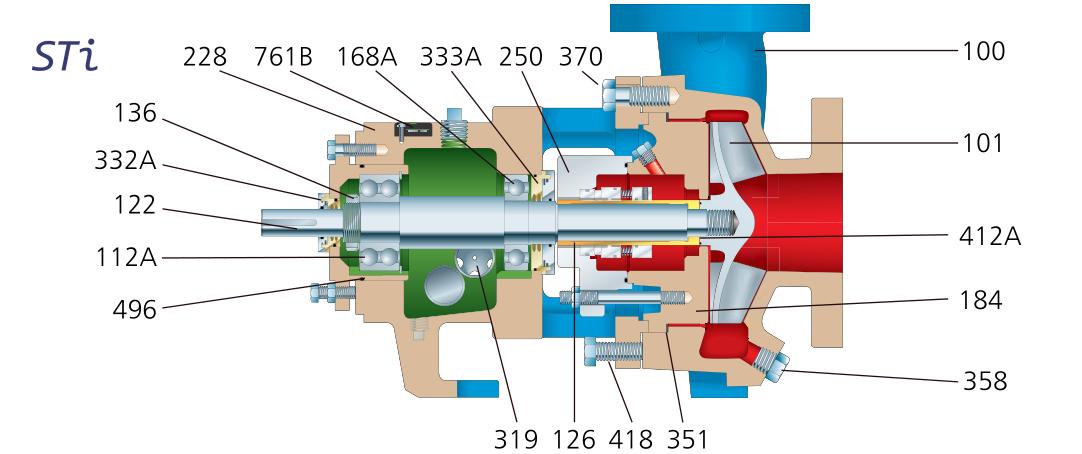

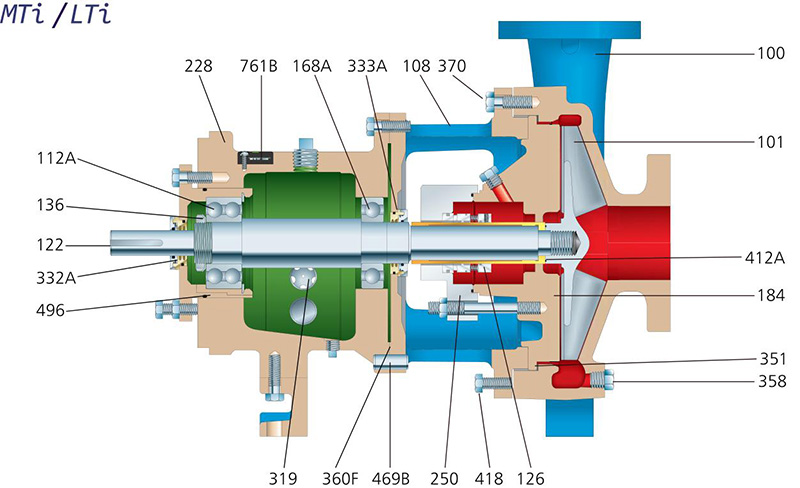

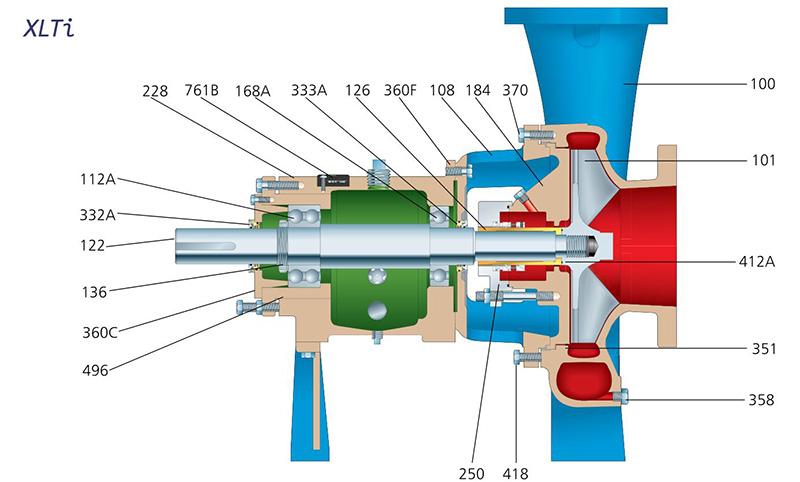

Impeller

Designed for long-term, maintainable performance and minimum hydraulic loads for

maximum reliability.

CASING

• Top centerline discharge for air handling, self-venting.

• Class 150 pumps have Class 300 wall thickness as standard.

• Back pull-out design.

• Integral feet.

Seal Chamber

Designed for favorable seal environment —proper heat dissipation and lubrication of seal faces.

The design must also be able to handle tough services: liquids containing solids, air or vapors.

Power End

Designed for optimum bearing life, effective oil cooling, and minimum shaft deflection. Onboard

condition monitoring provides early warning of potential failures, before they occur.

Related News

Submitted successfully

We will contact you as soon as possible