ANSI Pump Materials

1.Our pumps could be 100% interchangeble with leading enterprise’s 3196 series.

2.The wet ends material like Titanium, Nickel, Hastelloy C, A20, CD4M, 316SS, Cast Steel etc are all available.

The 3196 ANSI collection is to be had in a wide variety of sizes, capacities and substances to match absolutely any technique-fluid application.

RECEIVING THE PUMP

Inspect the pump as soon as it is received. Carefully check that everything is in good order. Make notes of damaged or missing items on the receipt and freight bill. File any claims with the transportation company as soon as possible.

STORAGE REQUIREMENTS

Short Term: (Less than 6 months) normal packaging procedure is designed to protect the pump during shipping. Upon receipt, store in a covered and dry location.

Long Term: (More than 6 months) Preservative treatment of bearings and machined surfaces will be required. Rotate shaft several times every 3 months.

Refer to driver and coupling manufacturers for their long term storage procedures. Store in a covered dry location.

NOTE: Long term storage treatment can be purchased with the initial pump order or can be applied to pumps already in the field that were not treated at the factory.

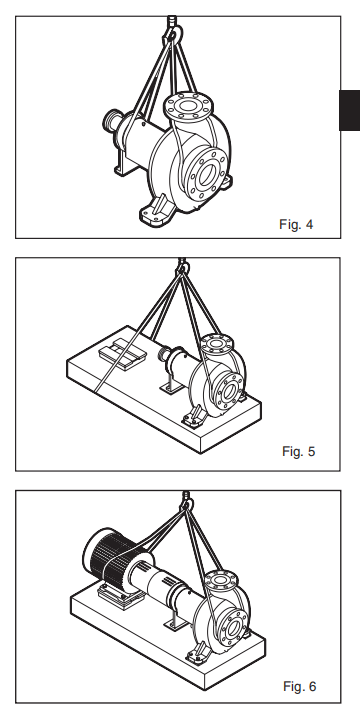

Pump and components are heavy. Failure to properly lift and support equipment could result in

serious physical injury or damage to pumps. Steel toed shoes must be worn at all times.

Use care when moving pumps. Lifting equipment must be able to adequately support the entire assembly. Hoist bare pump using a suitable sling,under the suction flange and bearing frame. Baseplate mounted units are moved with slings under the pump casing and driver. Refer to Figs. 4-7 for examples of proper lifting techniques.

WARNING

Refer to the Installation section of this manual for detailed instructions for lifting a ANSI Combo with installed equipment. Never lift a ANSI Combo with pump and motor mounted using the procedure shown in Fig. 5 and Fig.6

Related News

Submitted successfully

We will contact you as soon as possible